NeoStat® C2 ESD Bench Mats (anti-static)

NeoStat® C2 ESD Bench Mats – Premium quality, static dissipative bench mats for covering work bench surfaces in EPAs.

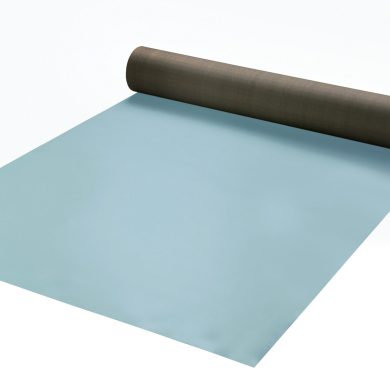

These anti static bench mats are made from an exceptionally tough, two layer static dissipative rubber material, 2mm thick, which is easy to maintain and has a long life. Available in a choice of blue and grey colour, a range of standard sizes, cut to customer requirements or in full rolls.

Textured top layer with excellent heat and solder resistant properties and conductive backing.

NeoStat® C2 ESD Bench Mats are designed for general purpose applications – either loose laid or adhered to work surfaces.

Note: tolerance on cut dimensions +/- 5mm

10mm press studs can be fitted as required – click here for available stud positions – when ordering enter the stud reference in the notes field. Unless requested at time of order, mats will be sent without 10mm press studs fitted .

Click here for cleaner recommended for NeoStat ESD bench mats.

Full rolls also available – click here for details

NeoStat C2 Bench Matting

Dissipative top-layer 108 Ω

Conductive bottom-layer 106 Ω

Typical resistance to ground 106 – 108 Ω

Main characteristics:

- Reflection breaking surface to reduce glare and improve operator comfort.

- Protection against small collisions thanks to natural resilience of rubber.

- Prevention of sliding of delicate components thanks to the excellent friction co-efficient of the material, which is increased by the embossed surface.

- Heating resistance: rubber does not melt and does not burn coming into contact with hot metal parts or soldering debris.

- Chemical resistance: please ask for detailed data sheet.

- Oil resistance: this product resists to most oils.

- Suitable to loose laying: this product does not require application with adhesive.

- Good resistance to scratches.

- Excellent flexibility and comfort.

Size and colours:

- Rolls 1.22m x 10m – 2 mm thickness (double layer); other sizes upon request.

- Available in light grey, light blue.

Physical and Mechanical Characteristics – Dissipative coloured top layer:

- Hardness (ISO 7619): 75 . 5 shore A.

- Abrasion resistance (ISO 4649, method A): ≤ 200 mm3.

- Indentation (EN 433): ≤ 0.20 mm.

- Chemical resistance (EN 423): resistant to chemical agents normally used for maintenance.

- Dimensional Stability (EN 434 – 6h/80°C): ≤ 0.4 %

Browser not supported

We recommend that you use the latest version of Chrome, Edge or Firefox.